- #Sheetcam plasma setup install#

- #Sheetcam plasma setup update#

- #Sheetcam plasma setup software#

- #Sheetcam plasma setup code#

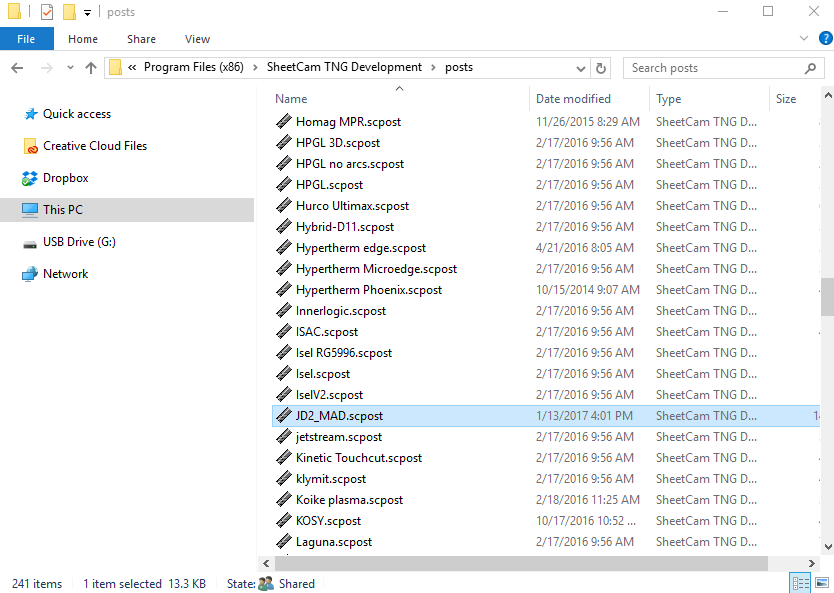

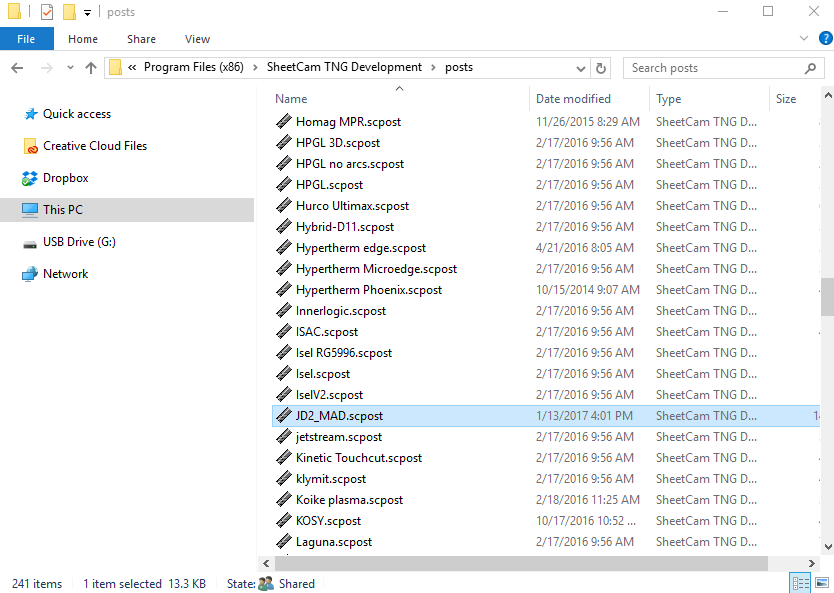

Fusion 360 now includes its very first Directed Energy Deposition (DED) platform, the Meltio M450. This post processor was created from a default laser cutting post processor with the following modifications to make it suitable for 2D Wire-EDM with Dynomotion CNC: -Removed all Z-axis moves (2D wire EDM machining only uses X and Y) -Changed all G0 moves This is the post processor step by step instructions for sheetcam. apart (typical system for sprocket mounting, etc). To date, the only piece that I have been able to machine is the Stepcraft logo provided as a sample file to test the machine following its construction. For sheetcam continue to stroll down further to " POST PROCESSING IN SHEETCAM FOR FIRECONTROL". #Sheetcam plasma setup install#

All I’m trying to do is install the post processor, fire control into the FUSION 360 posts folder, so I can post the G-code. #Sheetcam plasma setup code#

You can edit the line out of the code every time but that’s a drag, and there are no sttings to turn the output off.

#Sheetcam plasma setup software#

The post-processor is available from a link in the Software section of that page, along with instructions for using it in Fusion 360. I can manually command it fine, all good there. , so Ive had a Post Processor written specifically for the Shapeoko 3 (might work for the I have a deckel fp4a with grunding contour 3 control which is similar with Dialog 4. I am using Fusion 360 to generate tool paths and hopefully G-code to import directly into Easel for cutting on my new 1m X-Carve. I did a simple design in fustion 360, but what Post processor are recomended to use for creating the G code file? The “SolidCAD Universal FANUC” post processor (free on our website) contains a large number of parameters that can be set on-the-fly through the “Post-Process” dialog, without needing to change anything inside the post-processor. I suspect you possibly have the same output assigned in Mach for flood coolant and spindle/torch.Fusion post processor The past 18 months put pressure on finance leaders to answer key questions and gather insight from across different lines of business faster than ever before. Saying that my table still works fine, a M8 should not turn on you torch, I would say you have a setup or a wiring issue with your machine or Mach3. Hopfully someone at autodesk can look at this issue. #Sheetcam plasma setup update#

in tool library the post processor tab Milling tools etc have a coolant selection for post processing but cutting tools do not, It seems to me since the update cutting tools have defaulted to flood coolant but there is no coolant drop down selection or parameters to turn it off. I had a look through the code and the torchmate post processor has a coolant lookup table, this is due to it being used for both milling a profile cutting but I Think the problem is with the Tool Library in Fusion360. Hi, I just checked & mine is also now adding a M8 instruction since the fusion update. I've had to go in and modify the g code manually to change it back to M9 to get me by.

Any suggestions? Do I have mach3 set up wrong? I've tried to find some where in the tool library in fusion360 where I have something with the plasma and coolant configured wrong with no luck. I looked up M8 is to turn on the flood coolant on and M9 is to turn it off. Before the update the third line was N30 M9. I had your post processor working great on my homemade plasma table, Thank you. But just updated fusion360 and now when I post using this same post processor the third line in the code is N30 M8 which for some reason turns on the torch on my machine. Once it does its first touch n go it turns on and off like it should.

siemens-840d error Danger of collision due to tool radius compensation 1. post-proccesor philips cnc 532 5 axis 1.

Haas (pre-NGC) haas Post processor edit Help 1.

0 kommentar(er)

0 kommentar(er)